Pulling filar board is to show outside grain adds floorboard normally, once making a way is to grind arenaceous board, outside grain has straight grain, random grain (with grain) , ripple and whorl principal a few kinds.

1, pull a straight grain. It is the method that in stainless steel appearance machinery conflicts normally after treatment is handled, get outside state is linear grain. The treatment process that helps filar board can eliminate stainless steel board raw material appearance has scratch, and also have decorate effect effect wonderfully. Of this kind of grain also have filament grain and short silk grain, because this grain is to use 100 clean cloth or stainless steel to brush the appearance to plank to have linear or short line, and can pass the diameter that change steel brushs get different the grain of degree of finish.

2, grain of the chaos that pull silk (with grain) . Appearance arenaceous grain looks from far is by circuit the arenaceous grain of circuit is formed, vicinity is namely not norms random grain, it is by wheelhead fluctuation orders about irregular sway wear, eletroplate next chromatically. The appearance of this kind of grain is dumb smooth state, and make the request is very tall also.

3, the ripple that pull silk. Its make a technology is to use the machine that brush light or the axial campaign that the roll of the group uses on the machine that brush grain, so the grain that wave form receives after stainless steel appearance is brushed via grinding.

4, the whorl that pull silk. Its make processing technique have bit of distinguishing feature, it is to use small electric machinery first, its axis jacket has circular felt, secure small electric machinery on the desktop, become the angle that 60 ° order about with table brim even. Make procrastinate later board use board of fixed stainless steel, and procrastinate again even board on stick a polyester film along procrastinate board the brim, the intent is to restrain whorl speed. Can roll later so the linear shift of felt and mop, can be in stainless steel board the whorl grain that outside processing gets same width.

Stainless steel pulls silk is grain of filar of the idea outside stainless steel namely, this is a kind of processing technique of stainless steel only. Appearance is inferior smooth, face of attentive settle on has an a tiny bit of grain, but feel,do not come out. Than shining normally the stainless steel wear-resisting of the face, look more on class a few.

The technology that pull silk can lose stainless steel on sure degree board ply, be in normally 0.1~0.2mm. Other, because of human body especially the palm has comparative and exuberant grease and sweat fluid to secrete, stainless steel pulls filar board to often contact the fingerprint that can leave contrast to be being shown with the hand, need to time wipe.

The article arranges storage-rack.onsonhardware.com of processing factory of drill rod solder

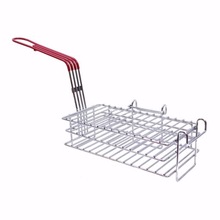

OSK06259 2017 Hot Selling direct factory Stainless Steel Rectangular French Fries Basket

OSK06259 2017 Hot Selling direct factory Stainless Steel Rectangular French Fries Basket OSK200310 Direct factory Stainless steel hot sale metal wire dish rack dish drying rack wall mounted dish rack

OSK200310 Direct factory Stainless steel hot sale metal wire dish rack dish drying rack wall mounted dish rack OSK200834 commerical kitchen Stainless Steel Fry Basket for Deep Fat Fryer,Rectangular Wire Colanders Oil Filter

OSK200834 commerical kitchen Stainless Steel Fry Basket for Deep Fat Fryer,Rectangular Wire Colanders Oil Filter OSK0201420 Full Size Stainless Steel Wire Cooling Rack / Pan Grate for Steam Table Pan

OSK0201420 Full Size Stainless Steel Wire Cooling Rack / Pan Grate for Steam Table Pan