A few sort stainless steel is chosen on industry, by metallographic arrangement cent is: Ferrite, Martens bodily form, austenite, austenite + ferrite and deposit sclerosis wait for stainless steel.

Austenite stainless steel, divide the 12~25% that contain chromium beyond, still contain Ni7 20% and other influential to steel function element, it has outstanding mechanical function, be able to bear or endure well corrode ability and more crackajack cold change function, the arrangement of the steel when heating is fixed, quench cannot aggrandizement, connect super-cooling to make sclerosis but greater progress intensity, be like again classics effectiveness for a given period of time, tensile strength can amount to 6b=1600~2800Mpa this kind of steel is the most typical the delegate is LGrl8Ni9Ti. The processability of cutting of delibrate metal data of function of treatment of cutting of 1 stainless steel is the difficult easy degree that shows data cutting is machined.

It has sure relativity, with 45 steel but cutting sex serves as 1, commonly used data is opposite but cutting sex Kr, can divide for 8 class, processability grade is 1 class (Kr=.8~1) , for data of very simple cutting, 8 class are data of very difficult cutting (Kr=0.15~0.5 of Kr stainless steel, it is opposite but the metallic data with cutting poorer sex, for example austenite stainless steel (LGrl8Ni9Ti) Kr=0.4, ferrite not pound steel (1Gr28) Kr=0.48, martensite stainless steel (2Grl 1.1 physics, mechanical function is right but the affects stainless steel physics of cutting sex, mechanical function is right cutting sex has very big effect, to cutting treatment brings many hardship. Pass experimental positive result. Because this is below normal temperature,stainless steel intensity, yield point does not compare general steel products tall, but mechanical function is tall below high temperature. : Machine sclerosis especially very big, the mechanical function of stainless steel is so far in cutting process outclass is general of rolled steel, its but cutting sex wants difference than general steel.

Because the endurance of stainless steel is great, strong to the affinity sex of other data, feel to it when other metal when, below sure pressure effect, with respect to meeting fit conglutinate: Presentative, of conglutinate idea lose by force, divide a decision at character of stainless steel oneself outside, still with property of photograph feeling data (hardness, outside surface roughness) and smooth condition is concerned between speed of pressure of environmental temperature, feeling, opposite motion and feeling appearance. Stainless steel is in cutting process, of cutting tool before knife face and the appearance that are cut to leave a metal: Be in very great pressure, very feel below Dou temperature and the very big condition relative to athletic speed, here the condition falls, the “ that very simple fit says commonly accumulates bits tumour ” . Because this cutting stainless steel compares general steel products,simpler fit “ accumulates bits tumour ” .

The fit of the tumour that accumulate bits has exasperate effect to workpiece surface roughness. And drop outside surface roughness is mechanical its are reached in production technology principal, also be to measure work precision work but cutting sex is principal index.

Intensity of big, high temperature cuts the endurance as a result of stainless steel in process of big, cutting bits not simple is curly and break off, such, can affect the success of the operation badly not merely, and cut bits can knead hold already machined appearance, influence in order to machine outside quality, and even bring about edge collapse to break. Accordingly, when cutting stainless steel, platoon bits, breaking bits is one of first issues that should ponder over processing. : (3) thermal conductivity needs an influence but cutting sex. Alloying element chromium, nickel makes except the strength that adds steel, endurance but outside cutting sex addle, it still dropped greatly the thermal conductivity of steel. For example 24% what X of coefficient of thermal conductivity of stainless steel LCrl8Ni9Ti is 45 steel only. So, its already were out of shape a deepness is corresponding tower above is very much.

Appearance of cutting tool exercise and temperature of spare parts appearance, to cutting treatment has first sense. To cutting tool, because temperature mixes tall cutting to feel the greater unit pressure on the face in cutting tool, make be dispersed quickly by the fit between treatment metal and cutting tool data, present felt idea. Cut bits and cutting tool periodic when sticking solder and it to come down from the depart on cutting tool, the particle cutting bits of conglutinate brings about cutting tool tatty to add, it is especially in interrupted cutting process, all the more of this kind of state is serious, make edge damage adroitly.

Article chapter out: storage-rack.onsonhardware.com/#

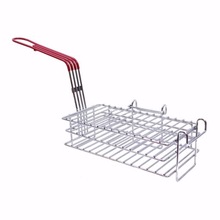

OSK06259 2017 Hot Selling direct factory Stainless Steel Rectangular French Fries Basket

OSK06259 2017 Hot Selling direct factory Stainless Steel Rectangular French Fries Basket OSK200310 Direct factory Stainless steel hot sale metal wire dish rack dish drying rack wall mounted dish rack

OSK200310 Direct factory Stainless steel hot sale metal wire dish rack dish drying rack wall mounted dish rack OSK200834 commerical kitchen Stainless Steel Fry Basket for Deep Fat Fryer,Rectangular Wire Colanders Oil Filter

OSK200834 commerical kitchen Stainless Steel Fry Basket for Deep Fat Fryer,Rectangular Wire Colanders Oil Filter OSK0201420 Full Size Stainless Steel Wire Cooling Rack / Pan Grate for Steam Table Pan

OSK0201420 Full Size Stainless Steel Wire Cooling Rack / Pan Grate for Steam Table Pan