The stainless steel that has according to home develops the current situation of argon equipment inside conduit, to Ф conduit of 426mm of 60 ~ Ф reachs bend solder quality, the operation is more convenient, save the characteristic that argon enrages, research and development argon fixture is filled inside conduit and bend welding line, practice use action is crackajack, to relatively banner, useful construction machines and tools furnished to argon inside stainless steel conduit.

1 overview

In process of construction of solder of arc of argon of stainless steel conduit, argon is being filled to enrage inside conduit is to solder the process is important one of link, argon gas is filled to solder to ensuring inside conduit the action with the decisive move since quality. Solder in nozzle of oil field stainless steel before in construction process, of solder mouth inside place full argon uses a data not standard, cause solder mouth to safeguard undesirable the botch that enrages with data and argon, affected soldering quality. For processing before when stainless steel nozzle solders inside it is good to fill argon to owe hold accuse to reach botch picture, easy happening a series of doubt such as oxidation of solder mouth inside, proper motion research and development have use dimensions wider, argon fixture is filled inside the solder mouth of the good qualities such as operation and economic argon gas easily.

Argon current situation rushs inside conduit of 2 stainless steel

It is before in process of construction of solder of arc of argon of stainless steel conduit, argon gas is filled to wait for a data to undertake sealing blocking up to welding line both sides in board of sponge of bubble of the colligation on gas-filled tube, paper normally inside conduit, although can reach sure action, but argon cannot rush inside applicable bend (see a picture 1) .

Although solder to ensuring,choose afore-mentioned methods quality produced sure effect, but put in following doubt and blemish:

Welding line of 2.1 pairs of bend is unwell use or action not aspiration;

2.2 choose bubble sponge to seal seal with rubber slab compare argon gas wastage is opposite bigger (12 ~ 15L/min) , seal a data demand to often be replaced, hard of mouth of satisfactory bend solder inside strong argon.

The article arranges storage-rack.onsonhardware.com of processing factory of drill rod solder

OSK05276 dierce factory home decorations moved metal over door clothes hanger rack

OSK05276 dierce factory home decorations moved metal over door clothes hanger rack OSK06941 Eco-friendly Stainless Steel Rectangular Cooking French Fries Wire Mesh Deep Frying Basket

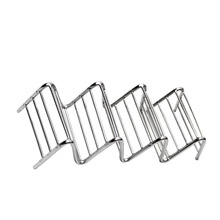

OSK06941 Eco-friendly Stainless Steel Rectangular Cooking French Fries Wire Mesh Deep Frying Basket OSK010026 Home&Restaurant Stainless Steel Taco Holder/ Stand/ Rack,Hold 3 Hard&Soft Taco Shells

OSK010026 Home&Restaurant Stainless Steel Taco Holder/ Stand/ Rack,Hold 3 Hard&Soft Taco Shells OSK2000374 Set Of 4 Chrome Chafer Food Warmer foldable Wire Frame Stand Rack Buffet Chafing Dish

OSK2000374 Set Of 4 Chrome Chafer Food Warmer foldable Wire Frame Stand Rack Buffet Chafing Dish