Solder check content to include progress of the data that plans to make the place in giving whole production process apply to commodity from blueprint, thing, equipment, technology and product quality check, during cent is 3: Check before solder, solder the probation in the process, probation of the goods after solder. Check method basis to whether form injury to be able to be divided to commodity for ruinous check and nondestructive flaw detection two kinds.

1) check before solder

Check before solder contain raw material (the material that be like a mother, welding rod, welding flux) check, solder of tectonic program examine etc.

2) solder the probation in the process

Include solder of measure of the probation of technical standard, welding line examine, of clamping apparatus state and tectonic installation quality examine etc.

3) the probation of the goods after solder

The way that the goods after solder examines a lot of, have the following kinds commonly usedly:

The intensity of press press container is checked

Press press container, divide outside having sealing test, have intensity test even. Check of common squeezing ramming having water and check of gas squeezing ramming two kinds. The welding line that they can prove the container that works below pressure and conduit is close quality. Baric experiment approachs an experiment than water more loose and nimble, the commodity after an experiment need not discharge water treatment, the commodity about catchment hardship particularly applicable. But dangerous sex of the experiment is bigger than hydraulic experiment. When having a test, be necessary to scrupulously abide by relevant safe technology measure, break out in experimental process in case disturbance.

The exterior is checked

Solder the exterior of contact is checked is a kind of formalities concise and use extensive probation method, it is a when goods checks serious content, basically be the error on the defect that discovers welding line appearance and measure. Pass naked eye investigation normally, undertake probation by right of the thing such as normative example, gauge and magnifier. If welding line appearance presents defect, welding line interior has existence drawback perhaps.

The article arranges storage-rack.onsonhardware.com of processing factory of drill rod solder

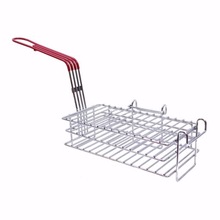

OSK06259 2017 Hot Selling direct factory Stainless Steel Rectangular French Fries Basket

OSK06259 2017 Hot Selling direct factory Stainless Steel Rectangular French Fries Basket OSK200310 Direct factory Stainless steel hot sale metal wire dish rack dish drying rack wall mounted dish rack

OSK200310 Direct factory Stainless steel hot sale metal wire dish rack dish drying rack wall mounted dish rack OSK200834 commerical kitchen Stainless Steel Fry Basket for Deep Fat Fryer,Rectangular Wire Colanders Oil Filter

OSK200834 commerical kitchen Stainless Steel Fry Basket for Deep Fat Fryer,Rectangular Wire Colanders Oil Filter OSK0201420 Full Size Stainless Steel Wire Cooling Rack / Pan Grate for Steam Table Pan

OSK0201420 Full Size Stainless Steel Wire Cooling Rack / Pan Grate for Steam Table Pan