When undertaking electric welding to weldment feed, should comply with is following criterion: ① shortens 2 times as far as possible loop length and the dimensional area that reduce loop place to include, with managing specific power consumption; ② reduces the ferromagnetic volume that extends return as far as possible, prevent to soldering especially bulk is extended to have bigger change when different solder is nodded, solder in order to reduce of electric current shake, make sure each nod quality judge calm (when applying labour frequency to communicate) .

1. All general welder all choose double-faced odd spot welding this plan. From feed of weldment both sides, apply to what each solder nods small-sized spare parts and large part periphery to solder.

2. Bosseyed odd spot welding is become the accessibility of a side electrode of the spare parts very poor or when 2 bigger, loop grow the spare parts too, can choose this plan. From feed of weldment odd side, need to consider another side to add cupreous mat to regard counterforce as in order to reduce billabong fulcrum.

3. Bosseyed double spot welding from a side feed as far as possible at the same time solder at 2 o'clock in order to improve productivity. Bosseyed feed often is put in invalid billabong phenomenon, botch electric energy, had been apart from a hour to will not solder when the dot. In certain circumstance, if the design agrees, going up board two rush one narrow long breach but shunt electric current drops considerably.

4. Although plan of double-faced double spot welding can apply on general welder, but the electric current between 2 o'clock hard equal apportionment, make sure quality is collective at 2 o'clock harder. And because choose method of push-pull type feed, shunt is mixed fluctuation board is inhomogenous heat the phenomenon is improved greatly, and solder dot can be decorated be in aleatoric position. The place that its are not worth exclusively is to must make 2 transformer, both sides of weldment of park of take leave of, this kind of plan also calls push-pull type spot welding. The electrify of two transformer needs to undertake by polarity.

5. Much spot welding is become check the number of the solder on the spare parts is more, when mass production, often choose much spot welding to plan in order to improve productivity. Machine of much spot welding all is special device, choose method of odd side feed for the most part, this method is more agile, 2 times loop does not get weldment measure control, in the requirement higher case falls, also can choose push-pull type spot welding to plan. Choose a group of transformer commonly now at the same time solder 2 or at 4 o'clock (latter has 2 groups of 2 second return) . Machine of a many spot welding can be comprised by many transformer. Can choose at the same time pressurization at the same time electrify, at the same time pressurization in group electrify and in group pressurization in group electrify plans 3 kinds. Can choose appropriate plan according to capacity of productivity, electrified wire netting.

More content: Hardware Storage Rack Www.onsonhardware.com

OSK20016 Direct factory Hot Sale Stainless Steel Fish Fry Basket For Deep Fat Fryer

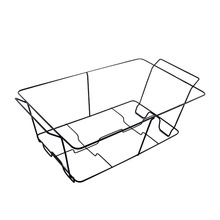

OSK20016 Direct factory Hot Sale Stainless Steel Fish Fry Basket For Deep Fat Fryer OSK0200630 hot sell Wire Chafing Dish Stand Catering Party Buffet Chafer Food Warmer Frame Rack

OSK0200630 hot sell Wire Chafing Dish Stand Catering Party Buffet Chafer Food Warmer Frame Rack