Avoid crystallization flaw solder method

Want to avoid the show effect of crystallization crackle, principal in be necessary to think how to cut down solder to impure content content, and how drop with proper construction way be out of shape the influence that to solder.

Drop the impure content content that solder

Drop the method of impure content content in solder path includes mother capable person and solder capable person two respects, as a result of,be in in the project data of mother capable person unqualified and what the example of the crystallization crackle of fit comparatives is much, for example of the armor plate of factory of some steel compose join much office of solder path appearance appeared crystallization crackle, classics assay analyses the carbon in finding out mother capable person, sulfur and phosphorous composition to exceed normative and normative value far, the impure content content in causing solder to also progresses relatively, and the fit that forms crystallization crackle. But, through choose impure content relatively inferior, composition is even and the solder material with smooth and steady quality, can drop considerably the machine rate that crystallization crackle breaks out.

Proper construction way

The throat depth lack that general solder or the fit machine that soak lack to also can increase fore-and-aft crackle are led. Solder path impersonates the crucial point character of the tensile stress that accepts two Duan Gang board and constrictive stress commonly. The throat depth that solder if lack or soak degree lack, mean the cut area that can accept stress (blue) narrowed, if the graph is shown 4 times, be like filament cannot suspensory heavy thing is common, craze of quite simple fit. Be like a graph 2 are shown, need only on the right side of solder condense shorten solder of left of stress serious offence accept power, left solder path can present chap picture at once.

Generally speaking, the throat depth that solder is very simple by visual reach gauge to come differentiate agrees with a standard, but, the endosmosis that solder degree is comparative and not easy by visual will investigate, be necessary to check skill to measure through blame attaint, or through solder the condition tries to investigate the endosmosis with solder path deep frit with the metallographic test that has attaint sex degree agrees with a standard.

Proper construction way is necessary to think board thick, thick board a chamfer, solder condition and solder method. With thick board for exemple clarify, general board thickness exceeds 17.5mm to be necessary to open slot, if pursue,5 are shown. Solder the solder fetch construction that method should collect two above, the first should be increased solder electric current or drop speed of divide with a hyphen at the end of a line will arrive abundant soaked intent, when the 2nd solders again with soldering appropriately the condition comes the request with satisfactory throat depth and senior role. When Qian Hu the path of solder of a straight angle of solder has contented frit deep soak with throat depth, solder way is natural have contented ability to accept solder metabolic influence.

Does in solder path terminal place often present chap? How to avoid with avoid?

Choose skill of Qian Hu solder to solder when long solder, often be in break out inside the solder path metal with solder adjacent end eventually fore-and-aft crackle is shown 6 times like the graph, general this kind of crackle is the crystallization crackle in be attributed to hot crack. This kind solders the fit element of crackle can use a figure 7 will clarify, should solder when electric arc is close to solder path terminal, solder path suffers electric arc heat to swell in A-A direction be out of shape, stretch in B-B direction fit together be out of shape, and of terminal guide although the cabined force of solder board can restrain his to be out of shape, but also can break out jointly below the effect that guides solder board is heated up in electric arc B ' - B ' of direction puffy, make consequently of B-B direction be out of shape stress restrains the effect fit is flabby, make the crystallization of ministry of terminal of fit solder path interstitial.

The article arranges storage-rack.onsonhardware.com of processing factory of drill rod solder

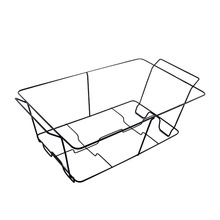

OSK0200533 Serve rite party city Buffet chafer food warmer wire frame / stand / rack full size chafing dish

OSK0200533 Serve rite party city Buffet chafer food warmer wire frame / stand / rack full size chafing dish OSK0200630 hot sell Wire Chafing Dish Stand Catering Party Buffet Chafer Food Warmer Frame Rack

OSK0200630 hot sell Wire Chafing Dish Stand Catering Party Buffet Chafer Food Warmer Frame Rack OSK03236 Stainless Steel Fry Basket for Deep Fat Fryer,Rectangular Wire Colanders Oil Filter K1021

OSK03236 Stainless Steel Fry Basket for Deep Fat Fryer,Rectangular Wire Colanders Oil Filter K1021