(1) solder makes test specimen be necessary to be being supervised usefully below, the request that presses skill appraisal plan strictly and regulation undertake.

(2) be opposite in the process that apply solder each process is due person specially assigned for a task is serious account, should equip the account of parameter account appearance that can withhold account data, account wants appropriate reservation, in order to have authorized.

(3) check a project to be necessary all ready, request to undertake by concerned regulations.

Principal check a project to have:

Does welding line exterior examine: ?

The nondestructive flaw detection of welding line examines: The ray flaw detection of test specimen tubal account undertakes by the regulation of DL/T821, welding line quality not under Ⅱ class standard. Nondestructive flaw detection is checked with solder contact is mechanical function is to do not have related, but " appraisal " in to soldering the knowledge of defect case is very necessary however, also consider together cutting when taking test piece, should grant to keep away from, in examining an item, be this to include is ought to. And fracture surface examines principal intent is to examine section of welding line metal microcosmic solder defect, be attributed to a solderer to operate skill to measure model of established rule or practice, cannot use at determining directly mechanical function, reason cancels.

Drawing experiment (measure sample)

The Yu Gao of ① sample with mechanical method take out, as neat as Mu Caiping.

The ply of ② test specimen: Complete ply test specimen can be used when ply is less than 30mm, two can be machined when ply is more than 30mm or multichip sample.

③ the tensile strength of every sample not the floor level under mother capable person.

The tensile strength of sample of ④ heterogeneous steel not under floor level of capable person of mother of inferior a side.

⑤ two or multichip sample has drawing test, the average of every groups of sample does not surpass the floor level that regulation of mother capable person is worth.

Labyrinthian experiment

① labyrinthian sample can be divided bend for transverse face (back) , fore-and-aft face is curved (back) , transverse side is curved.

② T is less than 10 when, t=t; When T is more than T, t = 10. The width of sample: 40, 20, 10 (unit: Mm) .

The Yu Gao of ③ sample with mechanical method take out, hold to mother capable person initiative appearance, bite edge and take out of disapprobation of solder root breach.

④ transverse side bends outside existence defect to answer with more austere measure for drawing face.

3 of check of reckon the actual amount after a discount of ⑤ influence music chief factors are: Of sample wide with compare thickly, labyrinthian viewpoint and curved axis diameter. The labyrinthian experiment method of SD340-89 regulations and the regulation that concern not as outspread as data oneself ratio is relative should, consequently, sample is labyrinthian outside the floor level value that outside and stretchy degree already transcended percentage elongation regulation to some rolled steel, cause is endless and reasonable.

To make labyrinthian experiment right plasticity determines more tend reasonable, new rules made following regulation: Labyrinthian experiment method presses metal of GB / T232 labyrinthian experiment method undertakes.

Regulation of labyrinthian experiment condition is: Sample ply ≤ 10, curved axis diameter (D)4t. Pedestal span (Lmm)6t+3, labyrinthian viewpoint 180 degrees.

About standard and skill condition regulation value of outspread rate floor level is less than the rolled steel of 20% , if labyrinthian experiment is unqualified, and actual measurement is worth % of outspread rate <20, promise to increase curved axis diameter to have a test, arrive zigzag after regular viewpoint, on the drawing face of every sample, there must not be length to surmount the craze defect of 3mm on any direction inside welding line and hot influence area, the crackle on the ability is outer, but answer as a result of the craze that place of slag inclusion defect causes plan into.

Pound experimental: ?

The article arranges storage-rack.onsonhardware.com of processing factory of drill rod solder

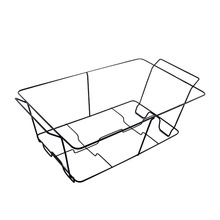

OSK0200533 Serve rite party city Buffet chafer food warmer wire frame / stand / rack full size chafing dish

OSK0200533 Serve rite party city Buffet chafer food warmer wire frame / stand / rack full size chafing dish OSK0200630 hot sell Wire Chafing Dish Stand Catering Party Buffet Chafer Food Warmer Frame Rack

OSK0200630 hot sell Wire Chafing Dish Stand Catering Party Buffet Chafer Food Warmer Frame Rack OSK03236 Stainless Steel Fry Basket for Deep Fat Fryer,Rectangular Wire Colanders Oil Filter K1021

OSK03236 Stainless Steel Fry Basket for Deep Fat Fryer,Rectangular Wire Colanders Oil Filter K1021