1, high temperature intensity is high, treatment sclerosis liability is big

With normally steel is compared, the intensity of stainless steel, hardness is not tall, but because contain very much Cr, Ni, Mn,wait for an element, plasticity and endurance are good, high temperature intensity is high, treatment sclerosis liability is big, consequently, cutting load is heavy. In addition, austenite stainless steel is in cutting process, interior returns meeting separate out a few carbide, accentuated the abrade effect to cutting tool

2, cutting muscularity

Stainless steel is out of shape in the plasticity in cutting process big, especially austenite stainless steel (the 1.5 times above that its percentage elongation surmounts 45 steel) , make cutting force is added

3, cut bits and picture of cutting tool felt austere

In cutting process generate the tumour that accumulate bits simply, affect treatment appearance surface roughness already, form cutting tool appearance simply to fall off again

4, cut bits to bend not easily with break off

Reach the cutting tool that shuts look bits partly to shutting, easy happening picture of the block that cut bits, make machine outside surface roughness to increase reach blade of cutting tool collapse

5, linear expansion coefficient is big

It is the half as much again of coefficient of carbon steel linear expansion about, below the effect of cutting temperature, workpiece produces heat simply to be out of shape and affect measure precision

6, coefficient of thermal conductivity is small

It is the 1/4~1/2 of coefficient of thermal conductivity of medium carbon steel about normally, cutting temperature is high, cutting tool wears away fast

The article arranges storage-rack.onsonhardware.com of processing factory of drill rod solder

OSK06941 Eco-friendly Stainless Steel Rectangular Cooking French Fries Wire Mesh Deep Frying Basket

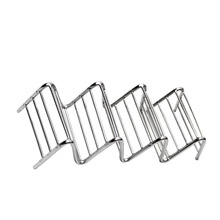

OSK06941 Eco-friendly Stainless Steel Rectangular Cooking French Fries Wire Mesh Deep Frying Basket OSK010026 Home&Restaurant Stainless Steel Taco Holder/ Stand/ Rack,Hold 3 Hard&Soft Taco Shells

OSK010026 Home&Restaurant Stainless Steel Taco Holder/ Stand/ Rack,Hold 3 Hard&Soft Taco Shells