Regard a famous market research and development of domestic, development, production, sale, work for as the large-scale diversification company at an organic whole, line of business of Shanghai sunshine pump makes limited company hold to “ to seek to live on with quality all along put, the major idea that seeks development ” with quality offers high grade work for for broad client! Together, line of business of Shanghai sunshine pump all along the promotion of actual strength of itself of prep bent on and what measure to producing quality is strict guard a pass, for this, at present not only system of the center of test of water pump function that has domestic top level, perfect unifinication work for, seasoned water pump expert, carry old development together, commodity obtains certificate of each professional attestation and client to approbate with quality of advantageous function, exquisite, crackajack work for public praise. Pass the indefatigable effort of the group, line of business of Shanghai sunshine pump already fetched very big gain now in profession of domestic water pump. So a sincere letter is this, the person that the water pump profession of duty overweight day aboves average, about water pump repair, conserve each are easy the face has from common method, look below together!

Pump of stainless steel magnetic force wields common mistake and broom:

The operation misgivings that pump of stainless steel magnetic force grew to perhaps operate personnel in the hour of the process be of use that apply presents breakdown is very regular job. Needed us to hold basic processing measure only, understand a few basic illness sweep measure, also can be over in the process that uses magnetic force pump so devoid need worry.

What does the common mistake that our just as well sees pump of stainless steel magnetic force under first have after all and sweep measure.

1, the in-house axis of pump of stainless steel magnetic force is broken off. Appear so the circumstance is to need to ravel magnetic force pump above all come down, pull down the part that break off next reinstall brand-new. After installing equipment normally next try out, so the problem also can handle the work with won't be affected normal again tantivy.

2, the bearing attaint of pump of stainless steel magnetic force also is one of common mistake. How should discover the time that bearing damages should do so? You need this time the austere rate that sees damage after all how, if the lax high of attaint and it is normal to won't be affected applying is without what hinder.

If damage,can be very austere, and do not use magnetic force pump apply this time to need to replace a new bearing in time normally, so come you are OK also in the process that uses magnetic force pump complete centering, and need not worry damages because of bearing this thing and those who affect magnetic force pump is normal apply.

Pump of stainless steel magnetic force uses a note:

1, because the refrigeration of bearing of magnetic force pump is mixed,lubricating is the medium that relies on to be carried, prohibit be being moved for nothing for certain so turn, prevent to be caused in the place when the restart after working midway power cut together spatio-temporal hold the job.

2, in the medium that be carried, if contain a lot ofsolid grain, pump entrance should add screen pack: If contain a lot ofiron magnetism qualitative particle, need to add magnetic filter.

3, pump should be less than 40 ℃ in temperature of the environment in applying, electric machinery temperature rise must not surmount 75 ℃ .

4, the medium that is carried and its temperature should be in pump material inside limit (detailed sees subordinate list) . Of metallic pump apply temperature <100 ℃ , when the <1.3 of proportion of medium of medium proportion ≤1.3; that is carried, influence skill function.

5, the medium that crystallizes for easy deposit about carrying fluid, seasonable cleanness answers after applying, the platoon accumulates fluid inside pump completely.

6, after sucking pump to run 500 hours oneself, should tear open check bearing and end panel to change the wear out condition of annulus, if the clearance of bearing and axle sleeve is more than 0.5 ~ 1mm, when impeller axial change moves 0.5 ~ 2mm, should replace bearing and axial to move link.

Read origin: storage-rack.onsonhardware.com/#

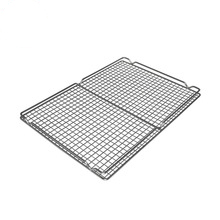

OSK07516 2017 hot sell Dual Baking Stainless Steel 304 Polished Stainless Steel Wire Cooling Rack

OSK07516 2017 hot sell Dual Baking Stainless Steel 304 Polished Stainless Steel Wire Cooling Rack