Yielding intensity (σ0.2)

The yielding dot of some metallic data extremely showing, measuring on have difficulty, consequently the yielding character to measure a data, regulation produces permanent and odd plasticity to be out of shape be equal to sure value (be former length normally 0.2% ) the stress when, call a condition yielding intensity or abbreviation are yielding intensity σ0.2.

Yielding dot (σs)

Rolled steel or sample are when drawing, exceed stretch limit when stress, although stress is added no longer, and rolled steel or sample still continue to break out the plasticity that showing is out of shape, call this picture yielding, and the value of the least stress when producing yielding picture is yielding dot namely. Set the outside force that Ps manages for yielding dot S, fo breaks an area for sample, σs=Ps/Fo(MPa) of yielding dot.

Percentage elongation (δs)

The data is in pull bring up the rear, the per cent of the length with its stretchy plasticity and former sample length makes percentage elongation or outspread rate.

Tensile strength (σb)

Expect in drawing process, from germinant the value of the greatest stress that reachs to the place when fit craze. It shows rolled steel revolts the ability large and small of craze. As corresponding as tensile strength still compressive strength, bending strength waits. The largest pulling force that before setting Pb to be pulled for the data, arrives, fo is sample sectional area, criterion tensile strength σb= Pb/Fo (MPa) .

5 Qu Jiang comparing (σs/σb)

The yielding dot of material (yielding intensity) the ratio with tensile strength, call Qu Jiang to compare. Qu Jiang comparing is bigger, the reliability of tectonic spare parts is higher, normally carbon steel Qu Jiang is compared for 0.6-0.65, steel of low alloy construction is steel of 0.65-0.75 alloy construction to be 0.84-0.86.

Hardness

Hardness shows the data revolts hard object to control its outside talent. It is one of main function targets of metallic data. Hardness is normally taller, wearability is better. Commonly used hardness target has hardness of cloth family name, Rockwell hardness and diamond pyramid hardness.

(1) Rockwell hardness (HR)

When HB>450 probably sample spends a hour, cannot choose experiment of hardness of cloth family name and convert Rockwell hardness is metric. It is to use the diamond cone of 120° of a vertex angle or diameter to be 1.59, the steel ball of 3.18mm, in appearance of the data that be measured is controlled below sure load, beg the hardness of contributive makings by the deepness of impress. According to experimental data hardness different, divide kind of different scale to make clear:

HRA: It is to choose 60kg load and diamond awl to be pressed implement gotten hardness, use at hardness extremely tall data (wait like hard alloy) .

HRB: It is to choose 100kg load and diametical 1.58mm the steel ball with hard temper by dipping in water, gotten hardness, use at the data with inferior hardness (like anneal steel, cast-iron etc) .

HRC: It is to choose 150kg load and diamond awl to be pressed implement gotten hardness, use at hardness very tall data (if quench steel) .

(2) diamond pyramid hardness (HV)

Awl controls the diamond square that is 136° with the load of 120kg less than and vertex angle implement control data appearance, the appearance that uses data impress indentation is accumulated except be worth with load, it is diamond pyramid hardness namely (HV) .

(3) hardness of cloth family name (HB)

With sure load (normally 3000kg) sure large and small (the diameter is 10mm normally) ball of hard steel of temper by dipping in water controls data appearance, hold period of time, after carry, the ratio of bear and its impress area, it is hardness of cloth family name namely (HB) .

Read origin: storage-rack.onsonhardware.com/#

OSK05276 dierce factory home decorations moved metal over door clothes hanger rack

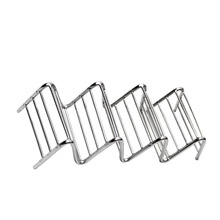

OSK05276 dierce factory home decorations moved metal over door clothes hanger rack OSK010026 Home&Restaurant Stainless Steel Taco Holder/ Stand/ Rack,Hold 3 Hard&Soft Taco Shells

OSK010026 Home&Restaurant Stainless Steel Taco Holder/ Stand/ Rack,Hold 3 Hard&Soft Taco Shells OSK200310 Direct factory Stainless steel hot sale metal wire dish rack dish drying rack wall mounted dish rack

OSK200310 Direct factory Stainless steel hot sale metal wire dish rack dish drying rack wall mounted dish rack