Equip to high-tech aviation establishment from family expenses tool now, solder of silver-colored drill rod has applied extensively at each domains as a science. Solder of silver-colored drill rod is to solder at first metal and metallic alloy, already extended the other utility outside be being used at join to divide a metal now, for instance pottery and porcelain is mixed cermet course of study. When a kind new material or it is existing material when new use appears, the job that solder of silver-colored drill rod often takes on to basically solder; With respect to this bit for, handlers or the personnel that prepare solder of executive drill rod should understand about soldering fundamental, finish welder smoothly to make with using assistance to choose correct solder alloy. Obtain more to help a reader the information of this respect, we listed the following and common problem to give solve:

1 , how to distinguish drill rod solder and other solder means?

Tell from the definition, the United States solders metal of association regulation fill (solder alloy) fused when C of ° of prep above 450 in the fused temperature under workpiece be solderinged, and alloy carries capillarity fill work form contact to be drill rod solder.

2, what is makings of silver-colored drill rod and makings of hard drill steel?

Above two kinds of term are to use descriptive argentiferous solder, but be slang or state means nonstandardly. Solder in what undertake below C of ° of prep above 450 the solder that it is drill rod, fall to be stannic solder under C of 450 ° conversely.

3, besides silver still other metal can use as stuff stuff (does drill rod expect) ?

Commonly used alloy besides silver, still have copper, cupreous phosphor, nickel, aluminium and gold.

4, why is makings of silver-colored drill rod so welcome?

Because makings of silver-colored drill rod is OK join is very much different metal, alloy etc material, and makings of silver-colored drill rod has inferior fuse is used more easily what temperature makes.

5, what is a capillarity?

The United States solders association regulation capillarity is to show fused soldering tin is going against gravity, in be apart very close workpiece surface forms the phenomenon of contact finally of flow.

6, what can affect a capillarity?

A lot of elements can affect a capillarity, solder the size of device aperture is main factor, and the osculatory area of workpiece be solderinged.

7, solder suitably how much is clearance?

To the connect of major level type, fill metal is the alloy of silver and cupreous phosphor, solder clearance recommends use 0.002-0.005 inch. Of course if you have any problems, the welcome contacts our technologist.

8, type of common connect of drill rod solder?

Basically 3 kinds solder contact type: To receiving form, build receive type and rabbet form, still have the different Composite that is 3 kinds of connect.

9, surface of influence mother capable person can what is main factor?

Contamination with oxide

10, what contamination to include?

The commonnest contamination has drawing to use lubricant, cutting fluid, polishing agent, engine oil reachs lube.

11, how purify oxide?

Solder the method that brazing flux is being used in the process is oxide of the most effective purify.

12, the brazing flux that there is different kind?

Have. According to brazing flux differentiate to basically have 3 kinds: Chemical, reductive airy and vacuum. Solder when alloy of use copper phosphor the workpiece of copper and copper when, phosphor can replace the action that purify oxide reachs since brazing flux.

13, can brazing flux use purify other contamination?

Not OK. Brazing flux is not detergent, deliquescent agent, degreasing agent, cannot use purify other contamination.

14, solder whether does purify answer to cream after the end shape brazing flux?

Should purify creams shape brazing flux. Because all creaming that shape brazing flux contains fluoride, stop to be able to change its connect intensity infirmly on workpiece.

15, heat is link soldering the importance in the process?

Heating impertinently is the main problem of solder of silver-colored drill rod, can affect the integrality of contact.

16, what is it is the most difficult in link to heat?

Should know when inside it is it is the most difficult in link to heat that the surface reachs even and proper temperature, because handlers cannot see inside the surface and also measure this surface hard in mass production.

17, the temperature that why agrees equably is very important?

The capillarity is the action mechanism that fill metal fuses and forms contact. The temperature that falls when whole capillarity area is achieved agree equably, fill alloy (drill rod expects) just can be gone to by drawing the hottest apparently.

18, does the even fill that adds heat energy to assure alloy of drill rod makings form joint?

Deny. Only by heating equably is to be able to 't make sure drill rod expects smoothly flow forms joint finally, drill rod solder needs a variety of technologies to be finished jointly. It is it is important to reach its that the professional skill of handlers gives a good connect to soldering. The be heated with the area even short of that is put possibly also below the capillarity additionally, below this kind of circumstance, drill rod makings is gone to by drawing below capillarity force recent cooperate a face to go up.

19, what is the distinction of makings of silver-colored drill rod and alloy of argentiferous copper phosphor?

Cupreous phosphor alloy (contain silver or do not contain silver) not as extensive as utility of makings of silver-colored drill rod, it basically uses the metallic data that solders to be mother capable person with copper. The phosphorous element in makings of cupreous phosphor drill rod also acted as the part of brazing flux. And makings of silver-colored drill rod solders besides the metal that can be used in cupreous phosphor alloy to use, on the work that also can be used at other metal to be mother capable person.

20, besides copper, still have other parent capable person alloy of applicable copper phosphor?

Cupreous phosphor alloy still can be used at brass, silver-colored, tungsten reachs the join of molybdenum. But brazing flux of these material need have the aid of are finished solder.

21, why cupreous phosphor alloy does not apply to iron, nickel is mother capable person solder?

Meeting and reaction of phosphorous generation metal produce iron and nickel element easy fragile phosphide weakens contact intensity.

22, what is solid photograph temperature, fluid photograph temperature?

When undertaking drill rod solder, achieve constant temperature to begin to fuse when drill rod makings it is solid photograph temperature namely; Achieve constant temperature to turn into completely when alloy liquid state is fluid photograph temperature.

23, what is low in all frit /In all brilliant?

Low in all frit / in all brilliant is to use a description to become alloy or it is temperature achieves change of some temperature alloy to be liquid term. Common Yin Gongjing alloy contains silver-colored 72% , contain cupreous 28% , in all brilliant temperature is 1435F.

24, what factor should when silver-colored drill rod expects, the choice consider?

Workpiece material, heat means, automation, intensity, internal pressure, working temperature, corrosion environment / medium, aid fusibility, extend a gender, conductibility and cost are very main consideration factor. Want to understand more message, the welcome contacts our technologist.

OSK20016 Direct factory Hot Sale Stainless Steel Fish Fry Basket For Deep Fat Fryer

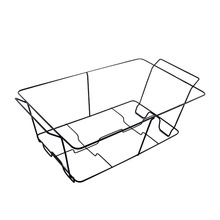

OSK20016 Direct factory Hot Sale Stainless Steel Fish Fry Basket For Deep Fat Fryer OSK0200630 hot sell Wire Chafing Dish Stand Catering Party Buffet Chafer Food Warmer Frame Rack

OSK0200630 hot sell Wire Chafing Dish Stand Catering Party Buffet Chafer Food Warmer Frame Rack